TheInternet of Things (IoT)is reshaping industries worldwide, offering unprecedented opportunities for businesses to increase efficiency, improve accuracy, and make smarter decisions.

TheTesting, Inspection, and Certification (TIC)industry is no exception. With IoT, the TIC sector is undergoing a transformation, driven by real-time monitoring, data accuracy, and predictive maintenance.

But what does this mean for TIC industry companies and their clients? Let’s take a closer look at how IoT is unlocking new possibilities in laboratory testing,inspection, andcertification servicesacross various industries, includingagriculture.

The Current Challenges in TIC Industry

Despite technological advancements, many challenges still exist within the TIC industry:

- Manual Data Collection: Reliance on human data gathering can lead to inefficiencies and inaccuracies.

- Delayed Inspections: Traditional inspections often occur at scheduled intervals, which means issues may go unnoticed until they’ve already caused damage.

- Disconnected Systems: Without a centralized system to connect data, getting a comprehensive overview of operations can be difficult.

By leveraging IoT solutions, companies can monitor systems in real time, reduce manual errors, and anticipate problems before they escalate—redefining the future of the TIC industry.

IoT Transforming TIC: The Key Benefits

IoT is proving to be a powerful tool for the TIC industry, offering a range of benefits that will drivetesting, inspection, and certification processesforward. Here’s how:

1-Real-Time Monitoring:

IoT sensors provide24/7 real-time monitoringof equipment and products, eliminating the need for constant on-site inspections.

This enables quicker response times and faster delivery of results to clients. In industries likeoil & gas,agriculture, and manufacturing, this leads to enhanced efficiency and safety.

2-Predictive Maintenance:

IoT-enabled devices can identify early signs of wear and tear or mechanical issues. This allows TIC companies to providepredictive maintenanceservices, helping clients resolve problems before they turn into costly breakdowns or compliance violations.

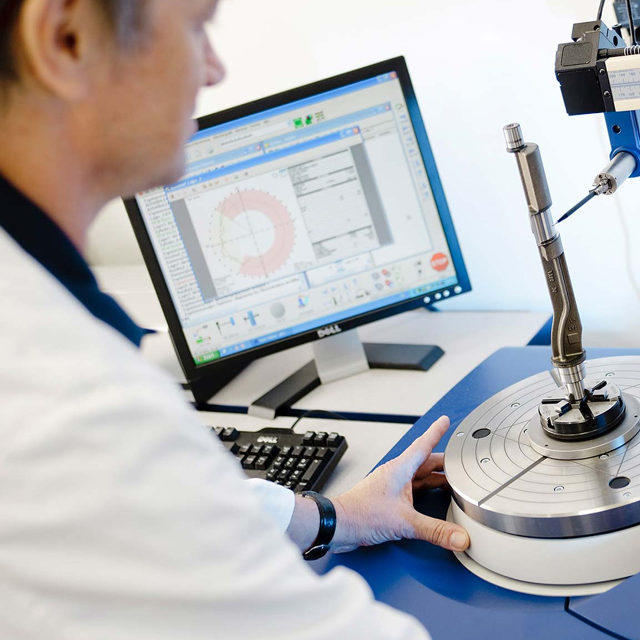

3-Increased Data Accuracy:

With IoT sensors automating data collection, the accuracy of inspections,laboratory testing, and testing increases. This is particularly critical for industries such aspharmaceuticals and food safety testing, where even small inaccuracies can have significant consequences.

4-Remote Inspections:

Remote inspections, facilitated by IoT, are revolutionizing the way TIC companies operate. Instead of waiting for inspectors to travel to a site, IoT sensors enableremote monitoring, allowing real-time assessments from anywhere. This is a significant innovation for industries likeagriculture, where monitoring supply chains and product quality is critical to ensuring safety and efficiency.

5-Enhanced Traceability with Blockchain:

When combined withblockchain technology, IoT ensures a transparent and secure record of all testing and certification activities. This provides clients with confidence in the accuracy and integrity of their data.

How IoT Enhances TIC Services: A Practical Example

Consider theAgriculture sector, where monitoring crop quality and food safety across vast supply chains can be complex and costly.

With IoT,smart sensorscan track temperature, humidity, and other key factors in real time, ensuring any anomalies are immediately flagged.

This not only improves operational efficiency but also significantly reduces the risk of contamination or spoilage—demonstrating the real-world value IoT brings tolaboratory testing,TIC of agriculture, and beyond.

The Future of IoT in the TIC Industry

Looking ahead, IoT will continue to drive innovation in the TIC industry. Some future trends include:

- AI-Powered IoT: Artificial intelligence (AI) will integrate with IoT to analyze data more effectively, predict failures more accurately, and optimize operational performance.

- IoT Drones and Robotics: Drones and robots equipped with IoT sensors will carry out inspections in hazardous or hard-to-reach areas, enhancing safety and productivity.

- Sustainability and Compliance: IoT will also support TIC companies in monitoring environmental impact, helping businesses remain compliant with regulations and reduce their carbon footprint

Conclusion : The Future is IoT-Driven

The IoT revolution is set to transform the waylaboratory testing,TIC of agriculture, andtesting, inspection, and certification servicesare delivered. At Tankoil, we’re committed to adopting the latestIoT technologiesto provide faster, more accurate, and more reliable solutions to our clients.

By leveragingIoT-based systemsforreal-time monitoringandpredictive maintenance, we’re ready to lead the charge in shaping the future of the TIC industry.

Industry Insights

1-Dutch company Shell and Malaysian company Petronas

are preparing to connect approximately 300 million cubic feet of gas per day from the production of the 10th and 11th phases at the Burullus fields in the West Delta region of Egypt by January

2- Egypt Signs Historic Hydrogen Cooperation Agreement with Bavaria .

In a significant step towards enhancing its position in the global hydrogen market, Egypt has signed a joint declaration of intent with the Bavarian government of Germany.

3- -5 key facts about the Robeiki City expansion project

This project is set to create 3,000 jobs, diversify Egypt’s manufacturing capabilities, and increase the country’s export potential.

4-10 key facts about Egypt’s vision 2030

These facts highlight how Egypt 2030 is shaping the nation’s future, with a strong focus on sustainability, social welfare, and economic reform